Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

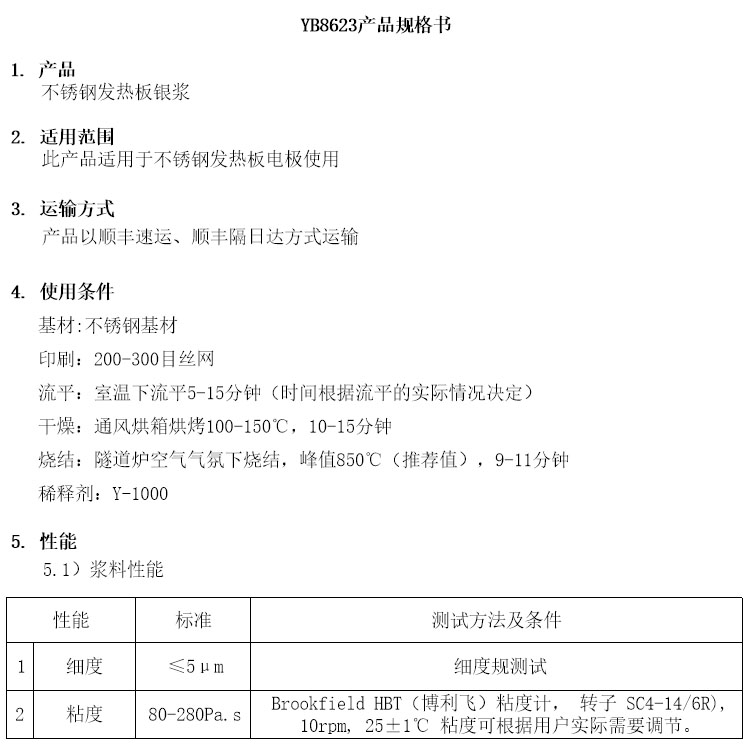

Stainless steel heating plate silver paste is a conductive silver paste applied to the stainless steel substrate during the production of stainless steel heating plates. It plays a crucial role in the production process of heating plates, affecting their conductivity, adhesion, welding resistance, and service life.

Product Features

High conductivity: Silver paste should have high conductivity to ensure that the heating plate can quickly and stably transmit current during operation.

Good adhesion: The silver layer should be firmly attached to the stainless steel substrate, not easily detached or damaged, to ensure the long-term stable operation of the heating plate.

Welding resistance: During the welding process, the silver layer should be able to withstand high temperatures without significant changes to ensure welding quality.

Stability: In harsh environments such as high temperature and high humidity, the silver layer should maintain stable conductivity and adhesion.

Preparation process

Raw material preparation: Prepare silver powder, glass powder, organic carrier and other raw materials in proportion.

Mixing and dispersion: Mix the powder with a carrier and mix them in a planetary mixer to allow the powder to be penetrated by the carrier and break into larger clumps.

Grinding: Transfer the mixed material to a three roll mill for grinding, and further break the agglomerates through a huge shear force, allowing the powder to completely penetrate into the carrier and form a uniform and delicate conductive silver paste.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2