Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

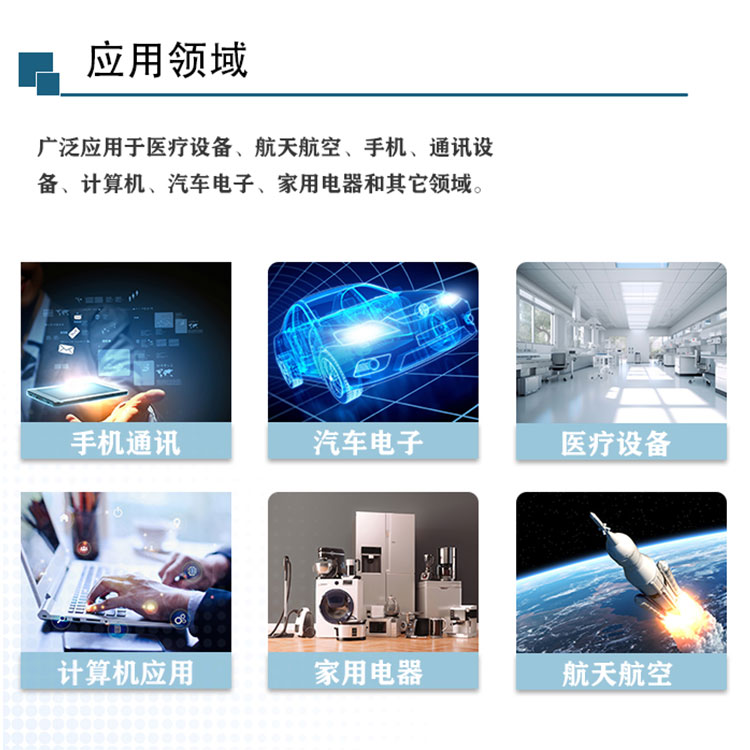

Advanced Institute Technology's piezoelectric ceramic filter special conductive silver paste uses high-quality silver powder and a special adhesive ratio to ensure excellent conductivity and adhesion. This product has undergone rigorous testing and can meet the working requirements of piezoelectric ceramic filters in high-frequency environments, providing stable electrical performance. Suitable for various ceramic materials, ensuring good frequency stability of the filter over a wide temperature range, it is an ideal choice for manufacturing high-performance piezoelectric ceramic filters.

+86-13826586185

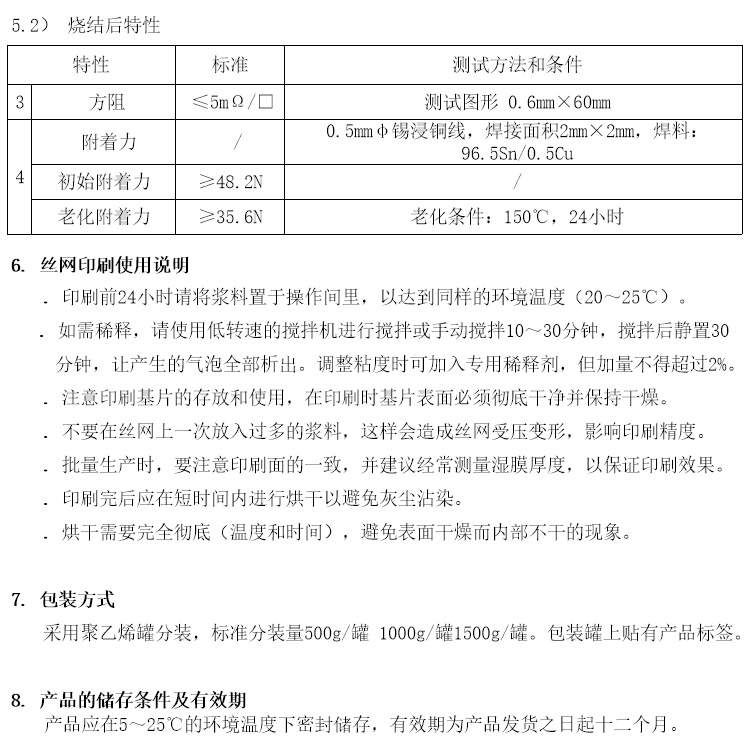

Piezoelectric ceramic filter conductive silver paste is a filling type conductive paste, and its conductive filler is mainly silver powder. It is mainly used in the metallization process of piezoelectric ceramic filters. Through chemical electroplating, spraying, sputtering, screen printing and other processes, a silver layer is coated on the ceramic dielectric body to form a silver conductive layer with high density, good adhesion, strong conductivity and good weldability.

Product Features

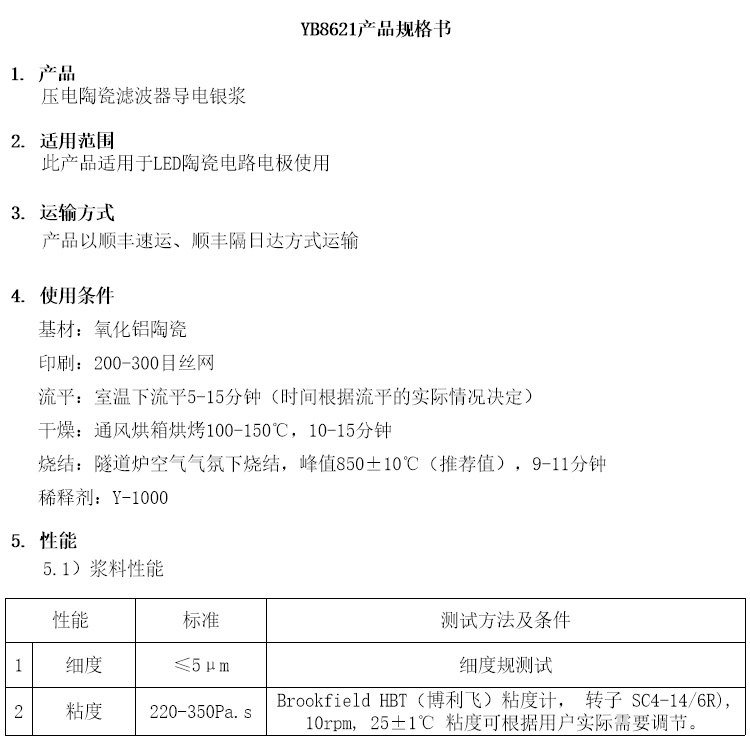

Conductivity: The silver content directly affects conductivity, and generally requires a silver content between 55% and 85%.

Viscosity: The viscosity range should be controlled within a certain range (such as 5-250 kcps/25 ℃) to ensure good fluidity and uniformity of the slurry during printing or spraying.

Sintering conditions: The sintering temperature and holding time need to be strictly controlled to ensure a good bond between the silver layer and the ceramic substrate, and to achieve the required electrical conductivity and mechanical strength.

Density and adhesion: The silver layer needs to have high density and good adhesion to ensure that it is not easily peeled off or damaged during long-term use.

Solderability: Conductive silver paste needs to have good weldability in order to be welded to other metal components in subsequent processes.

Piezoelectric ceramic filter conductive silver paste is a key material in the production process of ceramic dielectric filters, and its performance directly affects the signal transmission efficiency and stability of the filter. With the popularization of 5G technology and the expansion of the ceramic dielectric filter market, the demand for conductive silver paste will continue to grow. Therefore, the development of high-performance, low-cost, and environmentally friendly conductive silver paste has important market value and social significance.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2