Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Advanced Institute Technology has designed conductive silver paste specifically for laser etching process, which has extremely high processing accuracy and stability. By precise laser etching, fine circuit patterns are formed to meet the requirements of high-precision electronic devices. The high conductivity and corrosion resistance of silver paste ensure long-term stable operation of the circuit. Widely used in fields such as semiconductors, microelectronics, sensors, etc.

+86-13826586185

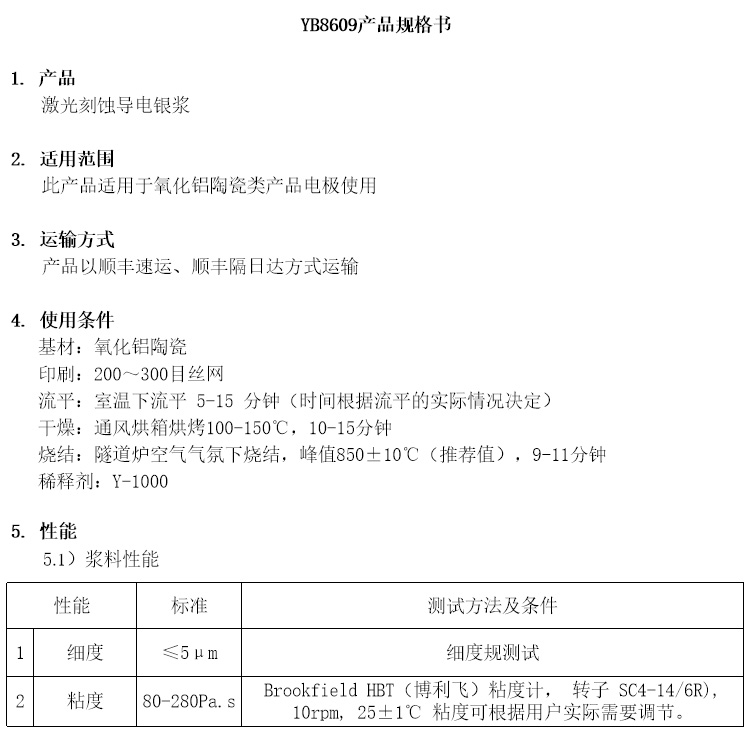

Laser etched conductive silver paste is a conductive material specifically used for laser processing technology, which combines the precision of laser etching with the conductivity of conductive silver paste, and has a wide range of applications in the field of electronic manufacturing.

Laser etched conductive silver paste is mainly refined from ultrafine silver powder and low-temperature cured thermoplastic resin. Among them, silver powder serves as a conductive filler, providing excellent conductivity; Thermoplastic resin acts as an adhesive phase to ensure the firm adhesion of silver powder to the substrate.

Product Features

Precise control: Laser etching technology can precisely control the deposition position and shape of silver paste, achieving micrometer or even nanometer level accuracy, meeting the manufacturing needs of high-precision electronic devices.

Efficient and fast: The laser heating process is rapid and can complete the formation of the conductive layer in a short period of time, improving production efficiency.

Good conductivity: Silver paste itself has excellent conductivity, and the conductive layer formed by laser etching technology also maintains high conductivity.

Oxidation resistance: Some laser etched conductive silver paste products such as CI-1016B have good oxidation resistance and can extend the service life of electronic devices.

Strong adhesion: Laser etched conductive silver paste has good adhesion with various substrates such as PET, PC, glass, etc., ensuring the stability and reliability of the conductive layer.

Application scope

Flexible Circuit: Laser etched conductive silver paste technology can be used to prepare flexible circuit boards, enabling more innovative designs such as bendable circuit boards and foldable circuits.

3D printed electronic devices: Combined with 3D printing technology, laser etched conductive silver paste can accurately print conductive lines and device structures in three-dimensional space, promoting the customization and personalized development of electronic device manufacturing.

Electronic packaging: In the packaging and connection of electronic devices, laser etching of conductive silver paste can achieve local soldering and connection, forming reliable circuit connections and packaging structures.

Sensor manufacturing: Laser etched conductive silver paste can also be used to prepare various sensors, such as pressure sensors, temperature sensors, and optical sensors, to improve the sensitivity and accuracy of sensors.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2