Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

+86-13826586185

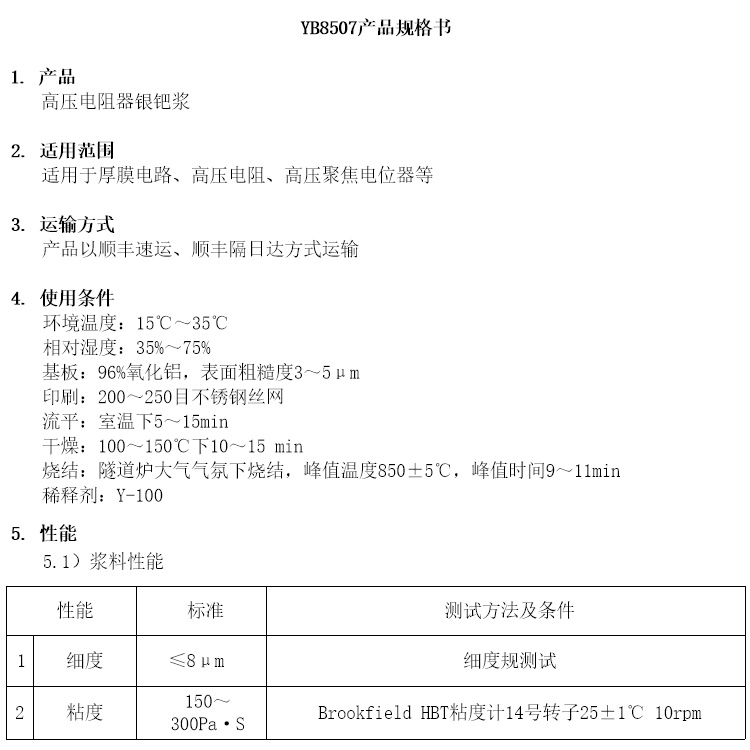

High voltage resistor silver palladium paste is a conductive paste designed specifically for high voltage resistors, mainly composed of silver powder, palladium powder, organic carriers, and inorganic additives. This slurry can form a stable conductive layer during the sintering process, providing reliable electrical connections for high-voltage resistors.

Product Features

Excellent conductivity: Silver and palladium are both excellent conductive materials, and silver palladium paste has excellent conductivity, which can meet the current transmission requirements of high-voltage resistors.

Heat resistance: High voltage resistors may generate high temperatures during operation, and silver palladium paste has good heat resistance and can maintain stable conductivity in high temperature environments.

Corrosion resistance: Silver palladium paste has good corrosion resistance to various chemicals and humid environments, which can extend the service life of high-voltage resistors.

Processability: Silver palladium paste has good fluidity and adhesion, making it easy to coat and sinter during the manufacturing process of high-voltage resistors.

Preparation method

Raw material preparation: High purity silver powder and palladium powder are selected as the main raw materials, and particle size control and surface treatment are carried out to ensure the stability and uniformity of the slurry performance.

Mixing and stirring: Mix the processed silver powder and palladium powder in a certain proportion, and add an appropriate amount of organic carrier and inorganic additives for thorough stirring and grinding to evenly disperse each component.

Filtering and impurity removal: Filter the evenly mixed slurry to remove impurities and particles, ensuring the purity of the slurry.

Drying molding: Drying the filtered slurry to remove solvents and moisture, forming a uniform resistance layer.

Sintering treatment: The resistance layer formed by drying is subjected to sintering treatment to improve its conductivity and mechanical strength. The selection of sintering temperature and time should be adjusted according to specific material and process requirements.

Workshop Display

High voltage focusing potentiometer silver palladium paste

High voltage focusing potentiometer silver palladium paste Speed control circuit thick film circuit silver palladium paste

Speed control circuit thick film circuit silver palladium paste Oil level sensor silver palladium paste

Oil level sensor silver palladium paste Thick film hybrid integrated circuit silver palladium paste

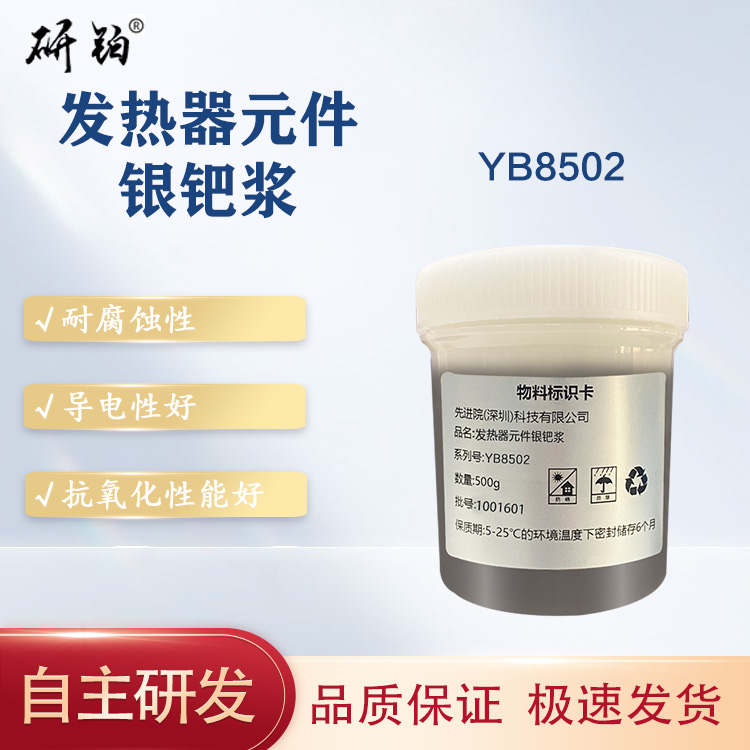

Thick film hybrid integrated circuit silver palladium paste Heating element silver palladium paste

Heating element silver palladium paste Heating electrode silver palladium slurry

Heating electrode silver palladium slurry

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2