Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

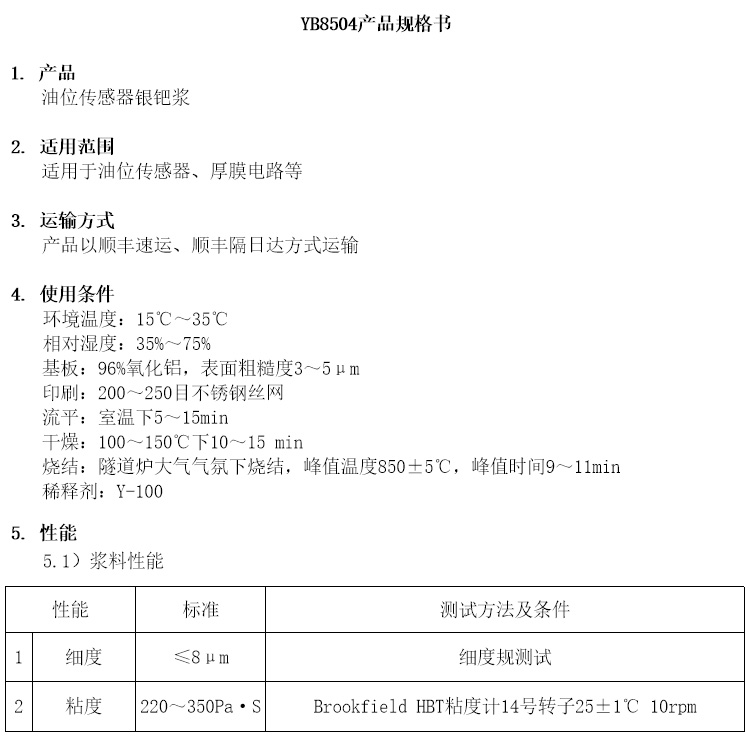

The silver palladium slurry for advanced institute technology oil level sensors is mainly composed of silver powder, palladium powder, glass powder, and organic carriers. Among them, silver powder provides good conductivity, while the addition of palladium powder enhances the wear resistance and corrosion resistance of the slurry. In addition, glass powder serves as a binder to firmly adhere metal powder to the substrate, while organic carriers are used to adjust the viscosity and flowability of the slurry.

+86-13826586185

The silver palladium paste used for oil level sensors is a material specifically designed for making conductive paths or electrodes in oil level sensors. This slurry is usually in the form of an alloy composed of silver and palladium, as both metals have good conductivity and chemical stability, and can resist oxidation and corrosion in harsh environments.

Product Features

Environmental friendliness: The product does not contain toxic elements such as lead and cadmium, complies with the European RoHS directive (2002/95/EC), and has superior environmental performance.

Strong adhesion: The silver palladium slurry has strong adhesion to the substrate material (such as alumina ceramics) and is not easily detached.

Wear resistance: The wear resistance of the slurry is improved by adding specific additives, such as pre treated polycrystalline cubic boron nitride powder.

Sulfurization resistance: Some products significantly enhance the sulfurization resistance of silver palladium conduction band by adding boron nickel solid solution powder and other additives, improving the working life and long-term reliability of oil level sensors.

Excellent conductivity: Silver palladium alloy has good conductivity, ensuring accurate transmission of oil level sensor signals.

Application scenarios

Automotive industry: Engine lubricant quality sensors, transmission fluid quality sensors, etc.

Aerospace: Monitor the contamination level of oil in aviation hydraulic systems to ensure the safe operation of aircraft.

Industrial manufacturing: Real time monitoring of oil contamination in mechanical equipment and hydraulic systems to prevent equipment failures and extend equipment lifespan.

Energy and electricity: Hydraulic system monitoring of equipment such as wind turbines.

Workshop Display

High voltage resistor silver palladium paste

High voltage resistor silver palladium paste High voltage focusing potentiometer silver palladium paste

High voltage focusing potentiometer silver palladium paste Speed control circuit thick film circuit silver palladium paste

Speed control circuit thick film circuit silver palladium paste Thick film hybrid integrated circuit silver palladium paste

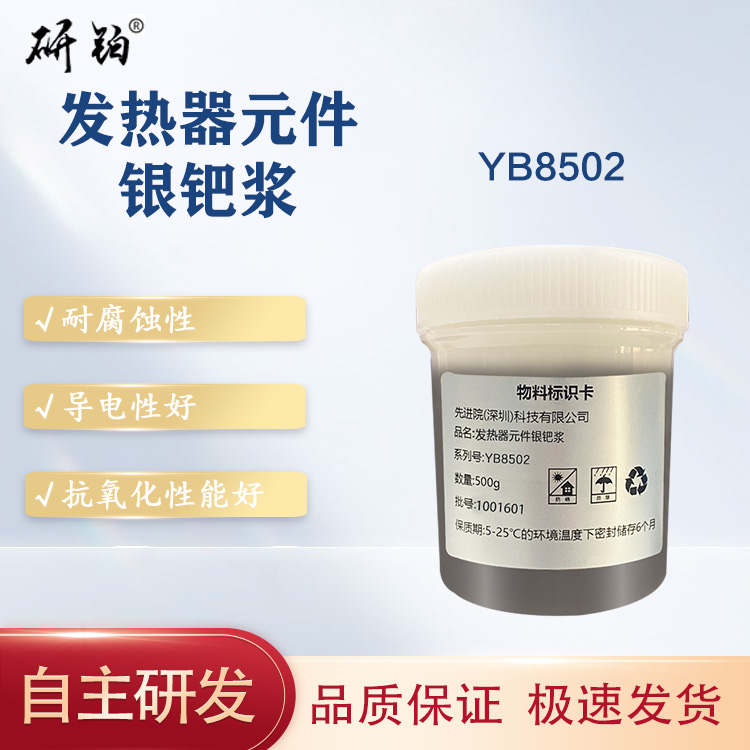

Thick film hybrid integrated circuit silver palladium paste Heating element silver palladium paste

Heating element silver palladium paste Heating electrode silver palladium slurry

Heating electrode silver palladium slurry

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2