Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

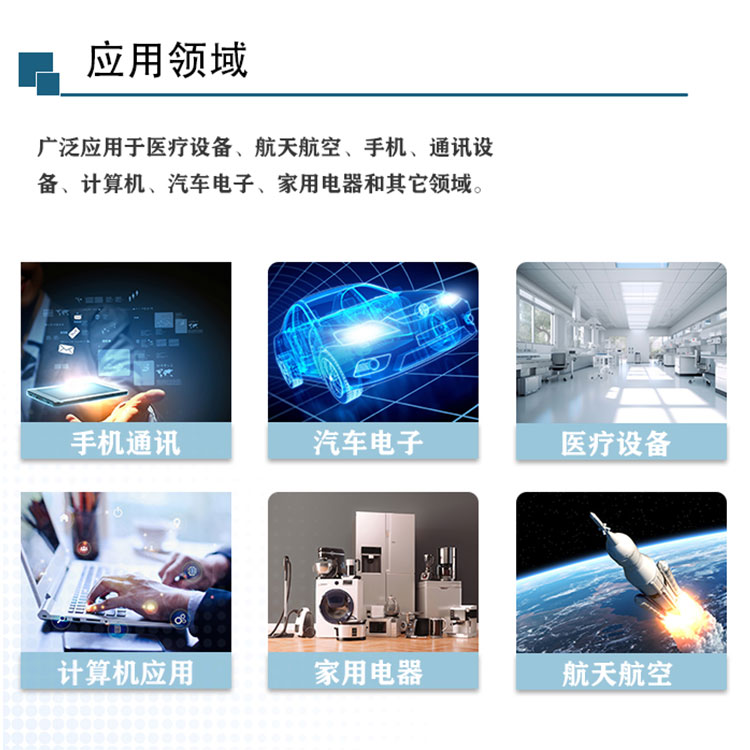

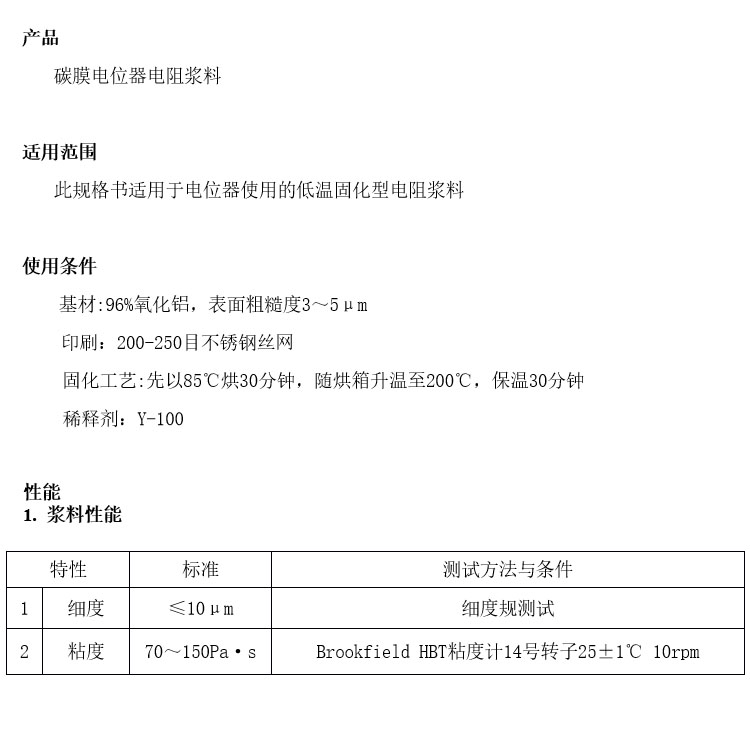

Carbon film potentiometer resistor paste is a key material for making carbon film potentiometers, which is made by mixing carbon powder and organic binder. This slurry forms a uniform carbon film on the substrate, and changes the resistance value by sliding contacts in contact with the carbon film, thereby achieving the function of potential adjustment. Carbon film potentiometer resistor paste has the advantages of low cost, stable performance, and wide adjustment range, and is widely used in audio equipment, instruments, household appliances, and other fields.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Carbon film potentiometer resistor paste is a mixture composed of conductive powders (such as carbon black, graphite, etc.), organic solvents, and adhesives. This slurry is coated on the surface of a substrate (such as ceramics, glass, etc.) through a specific process, and after drying and carbonization treatment, a uniform carbon film is formed to achieve the function of adjusting resistance.

Product Features

Good conductivity: The conductive powder in the resistance paste can provide good conductivity, ensuring that the carbon film potentiometer has accurate resistance adjustment function.

Strong bonding ability: The adhesive in the slurry can increase the bonding ability of the slurry, allowing the carbon film to uniformly adhere to the surface of the substrate and not easily fall off.

Good high temperature resistance: After carbonization treatment, the resistance paste can maintain stable performance in high temperature environments and is suitable for various special working environments.

Adjustable: The formula and process of the resistance paste can be adjusted according to specific needs to meet the requirements of different resistance values and application scenarios.

Production process

Raw material preparation: Select appropriate conductive powders, organic solvents, adhesives, and other raw materials.

Mixed preparation: Mix conductive powder, organic solvent, and adhesive in a certain proportion to form a resistive paste.

Coating process: Apply the resistance paste evenly on the surface of the substrate, using methods such as scraping and spraying.

Drying treatment: Dry the substrate coated with resistance paste to evaporate the solvent in the paste and form a uniform film layer.

Carbonization treatment: Carbonization treatment is carried out on the film layer at high temperature to thermally decompose the organic matter in the slurry, convert it into carbon, and improve the conductivity and stability of the film layer.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2