Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

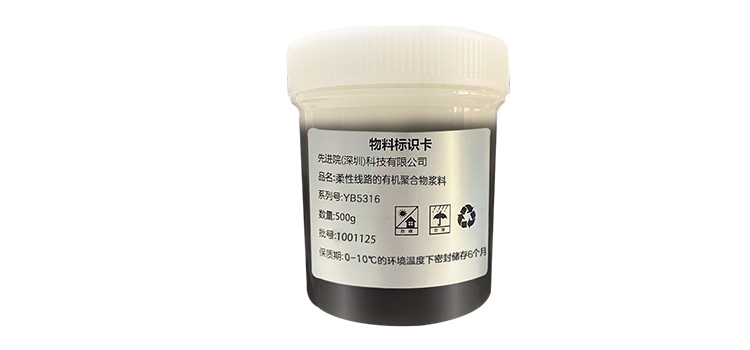

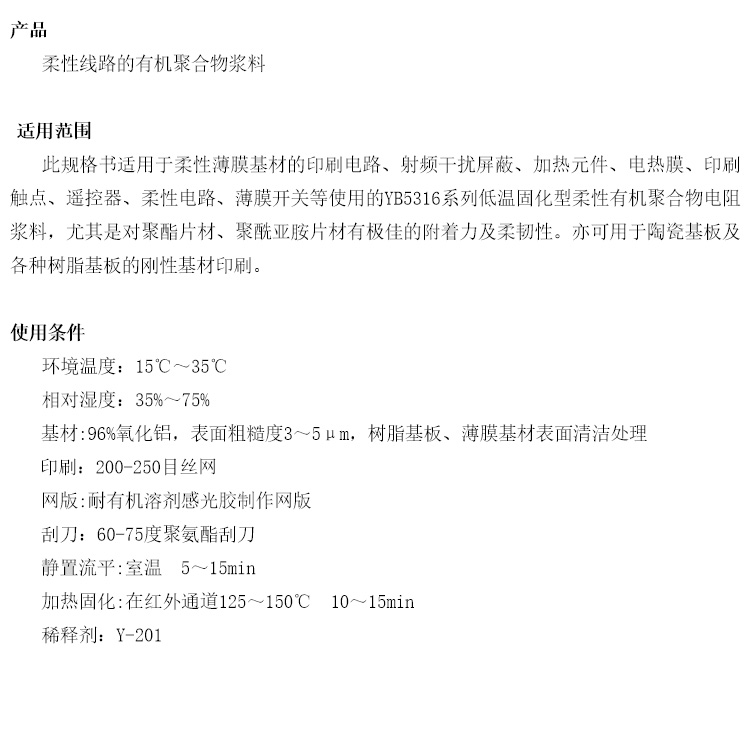

Organic polymer paste for flexible circuits is an electronic paste designed specifically for flexible electronic products, with excellent flexibility and bending resistance. This slurry usually contains organic polymers as binders, combined with conductive fillers such as metal particles, carbon nanotubes, etc. The organic polymer slurry of flexible circuits has a wide range of applications in wearable devices, flexible displays, smart labels, and other fields, providing reliable electrical connections and signal transmission functions for these devices.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

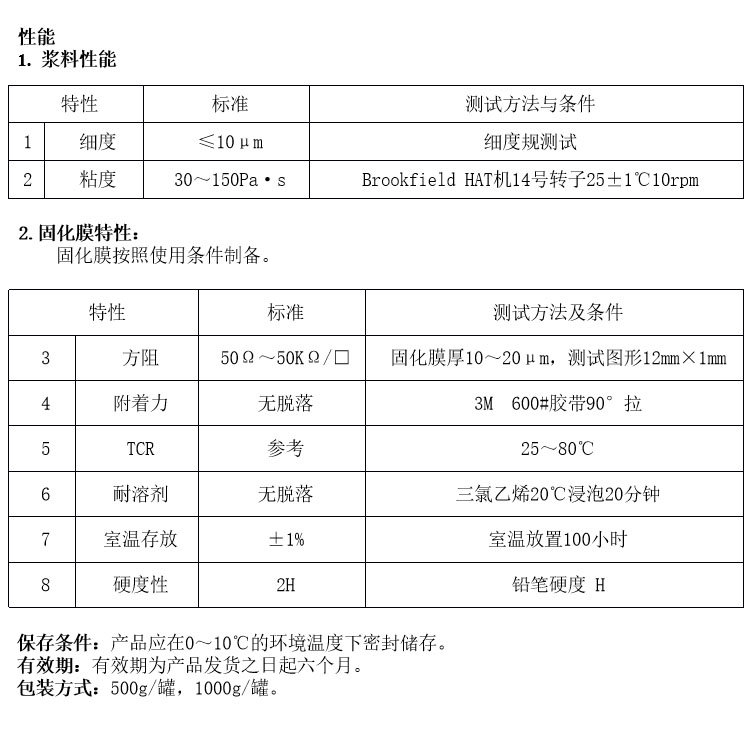

Organic polymer slurry for flexible circuits is a key material used to manufacture flexible electronic components. It mainly consists of solid particles or organic liquid mixed systems composed of powdered conductive metals, inorganic or polymer binders suspended in organic carriers.

Product Features

Flexibility: The line formed by the solidification of the slurry can withstand bending and twisting without affecting conductivity.

Conductivity: It can provide good electrical conductivity and is suitable for low voltage and high frequency applications.

Adhesion: Has good adhesion to flexible substrates and is not easily peeled off.

Environmental stability: Maintain stable performance under different temperature and humidity conditions.

Environmental friendliness: The slurry design complies with RoHS (Restriction of Hazardous Substances) standards and does not contain harmful substances such as lead, cadmium, mercury, etc.

Production process

Mixing: Mix conductive fillers, adhesives, solvents, and additives in proportion.

Grinding: Use a ball mill or sand mill to grind the mixture to ensure uniform dispersion.

Printing: Using techniques such as screen printing, gravure printing, or inkjet printing to apply a slurry onto a substrate.

Curing: Heating at a set temperature to evaporate the solvent, solidify the adhesive, and form a conductive path.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2