Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

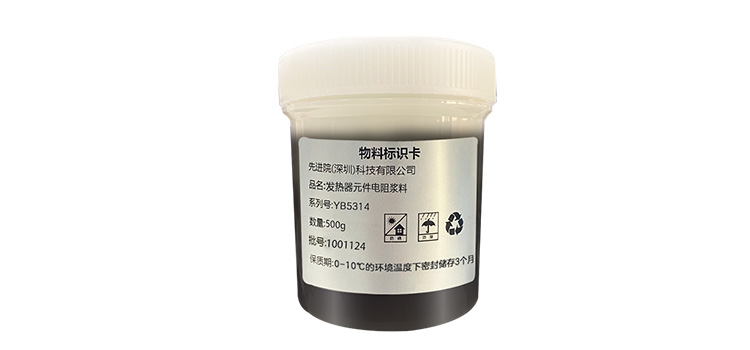

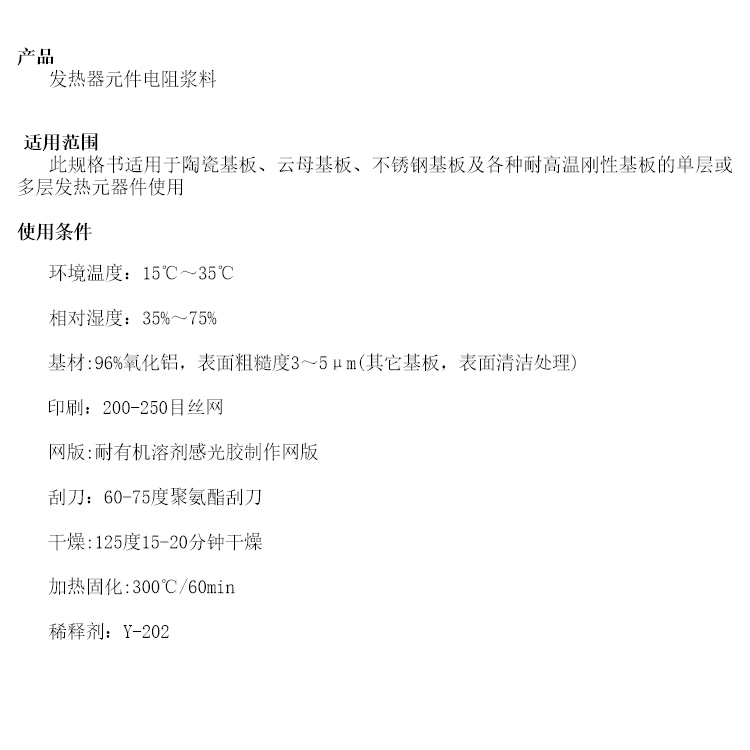

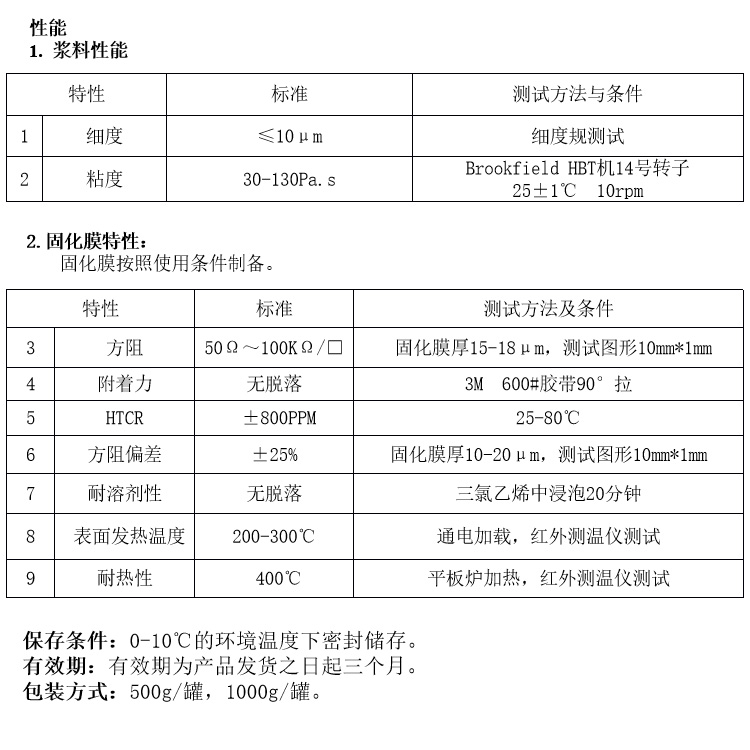

The resistor paste for heater components is an electronic paste designed specifically for heaters, used to convert electrical energy into thermal energy. This type of slurry usually has high electrical resistivity and good thermal stability, and can maintain stable heating power and temperature under long-term electrification. The resistance paste of heating element is widely used in household appliances and industrial heating equipment such as electric heaters, electric blankets, and electric heaters, and is a key component for these devices to achieve thermal energy output.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Heating element resistor paste is a high-tech electronic functional material specifically used for manufacturing heating elements. It is usually made by uniformly mixing solid powders (such as metal oxides, conductive fillers, etc.) and organic solvents to form a paste like substance. It can form a conductive layer with a specific resistance value after sintering, thereby achieving heating function.

Product Features

High thermal efficiency: capable of efficiently converting electrical energy into thermal energy.

Stability: Maintain stable resistance value during long-term operation and temperature changes.

Durability: It has a long service life and can resist chemical corrosion and mechanical wear.

Temperature control: The slurry formula can achieve temperature self limiting function, which automatically reduces the heating power when the temperature reaches a certain level.

Production process

Slurry preparation: Mix the above components in specific proportions to form a uniform slurry.

Coating: Coating the slurry onto inorganic substrates (such as ceramics, glass, silicon nitride) through screen printing, spraying, or other coating techniques to form a predetermined pattern.

Pre drying: Pre drying is performed at a lower temperature to remove some organic carriers and prevent the formation of bubbles during sintering.

Sintering: Sintering is carried out at high temperature to melt the glass phase, completely decompose the organic carrier, and form a stable resistive film.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2