Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

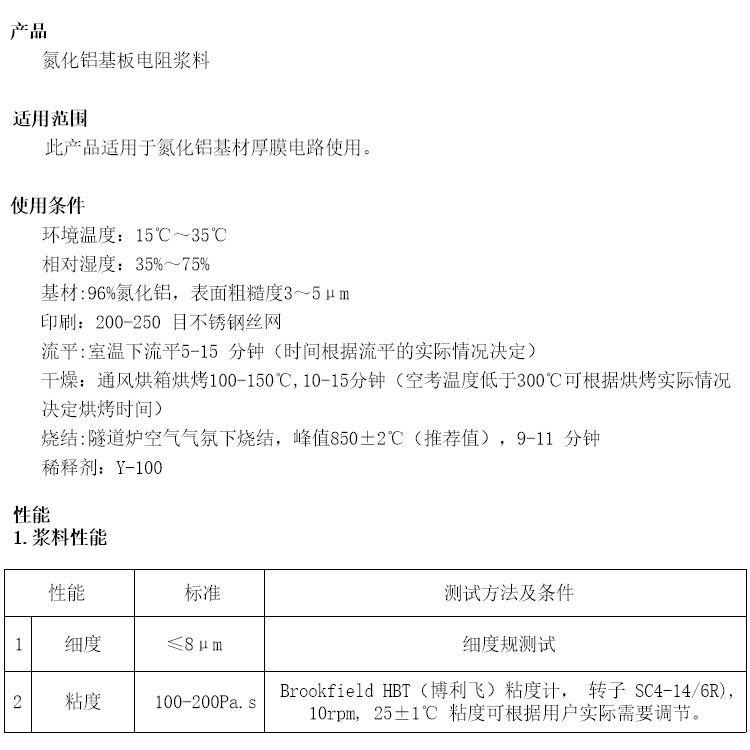

Aluminum nitride substrate resistor paste combines the characteristics of high thermal conductivity and low thermal expansion coefficient, making it particularly suitable for applications that require efficient heat dissipation and high dimensional stability. This slurry can effectively reduce heat accumulation and extend the service life of electronic components, making it an ideal choice for LED lighting, laser diodes, and high-frequency electronic devices.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Aluminum nitride substrate resistor paste is a high-performance and highly reliable conductive material designed specifically for aluminum nitride substrates. It has good thermal conductivity, adhesion, resistance control accuracy, and temperature stability, and is widely used in the manufacturing of high-power, high-density electronic devices. With the continuous development of microelectronic packaging technology, the market demand for aluminum nitride substrate resistance paste will continue to grow.

Product Features

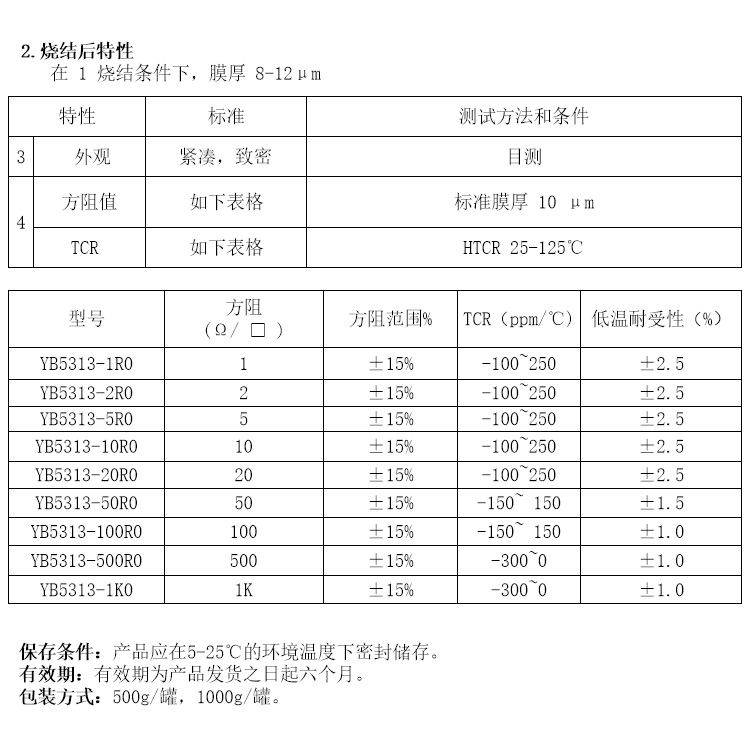

High thermal stability: able to maintain a stable resistance value in high temperature environments.

Low temperature coefficient of resistance: ensures that the resistance value changes little with temperature, improving the stability of the circuit.

Compatibility: Match with the thermal expansion coefficient of aluminum nitride substrate to reduce thermal stress.

High reliability: Maintain stable performance through repeated thermal cycles, and are not prone to cracking or peeling.

Production process

Printing or coating: Use methods such as screen printing, inkjet printing, or spin coating to coat the slurry onto an aluminum nitride substrate.

Pre drying: Remove some solvents to prevent the formation of bubbles during sintering.

Sintering: Sintering is carried out at high temperatures (usually 800 ° C to 1000 ° C) to completely decompose the organic carrier, melt the glass phase, and form a stable resistive film of the conductive phase.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2