Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

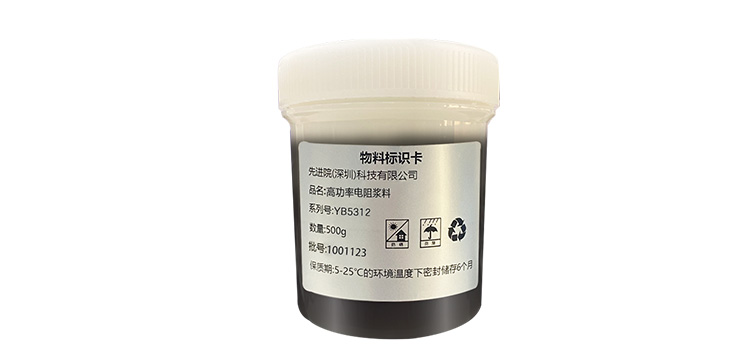

High power resistor paste is designed to meet the demands of high current and high energy dissipation, with excellent heat dissipation performance and high temperature resistance. It can stably withstand long-term high-power operation, ensuring the safe operation of the circuit in harsh environments. Suitable for power amplifiers, frequency converters, and high-power power supplies, it is the foundation for achieving high-performance electrical systems.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

High power resistor paste is mainly composed of conductive phase, insulating phase (such as ceramic powder), binder (such as glass powder), and organic carrier. Among them, the conductive phase is usually made of highly conductive metal powders (such as silver, palladium, etc.), the insulating phase is used to improve resistivity and temperature resistance, the binder plays a role in bonding the conductive and insulating phases together, and the organic carrier is used to adjust the fluidity and printing performance of the slurry.

Product Features

High power density: High power resistor paste can withstand high power density and is suitable for situations that require high current and high voltage.

High precision: Through precise formula and process control, accurate control of resistance values can be achieved to meet the needs of high-precision resistance components.

Good stability: It has excellent re firing stability and temperature stability, and can operate stably for a long time in harsh environments.

Environmental friendliness: Some high-power resistor pastes do not contain harmful elements such as lead and cadmium, meeting environmental requirements.

Production process

Printing or coating: High power resistor paste is coated on ceramic substrates through methods such as screen printing, inkjet printing, or spin coating.

Pre drying: After printing or coating, the slurry needs to undergo pre drying to remove some solvents and prevent the formation of bubbles during sintering.

Sintering: Sintering at high temperature, the organic carrier is removed, and the conductive phase and glass phase form a tight bond, thereby forming a high-power resistive film.

Post processing: including cooling, cutting, electrode welding, and final testing.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2