Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

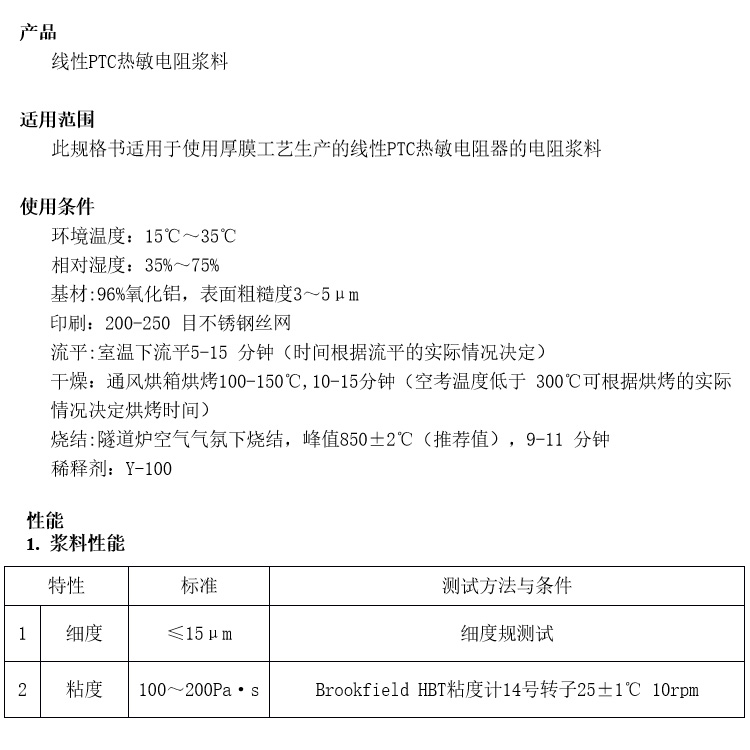

Linear PTC (Positive Temperature Coefficient) thermistor paste is designed specifically for precise temperature control applications. The slurry has a low resistance value at room temperature, and as the temperature increases, the resistance increases linearly, ensuring that the circuit automatically adjusts the current when overheated and protects the equipment from damage. Suitable for power management, battery pack protection, and overheating protection of electronic devices. Its stable performance and excellent reliability make it an indispensable component of modern electronic products.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Linear PTC thermistor paste is a special formula electronic paste designed specifically for the preparation of PTC thermistors. It utilizes the temperature sensitive properties of semiconductor materials to exhibit linear changes in resistance values or approximate linear changes within a specific range when temperature changes, thereby achieving precise sensing and control of temperature.

Product Features

Linear characteristics: Linear PTC thermistor paste is designed to provide relatively linear resistance temperature (R-T) characteristics over a wide temperature range, where the resistance value increases linearly with temperature rather than increasing step by step.

Stability: It has good thermal stability and reliability, and can maintain stable resistance change characteristics in high temperature environments.

Environmental friendliness: It usually does not contain toxic elements such as lead and cadmium, and complies with environmental standards such as the European RoHS directive.

Electrical performance: It has low electrical resistivity, high voltage resistance, and good ohmic contact performance.

Production process

Raw material preparation: Weigh the conductive phase, bonding phase, organic carrier, and additives in a certain proportion.

Mixing and stirring: Mix the raw materials and stir thoroughly to ensure uniform dispersion of each component.

Printing: Printing the paste onto a substrate through screen printing or other methods to form the desired pattern.

Drying: Drying the slurry at an appropriate temperature to remove solvents from the organic carrier.

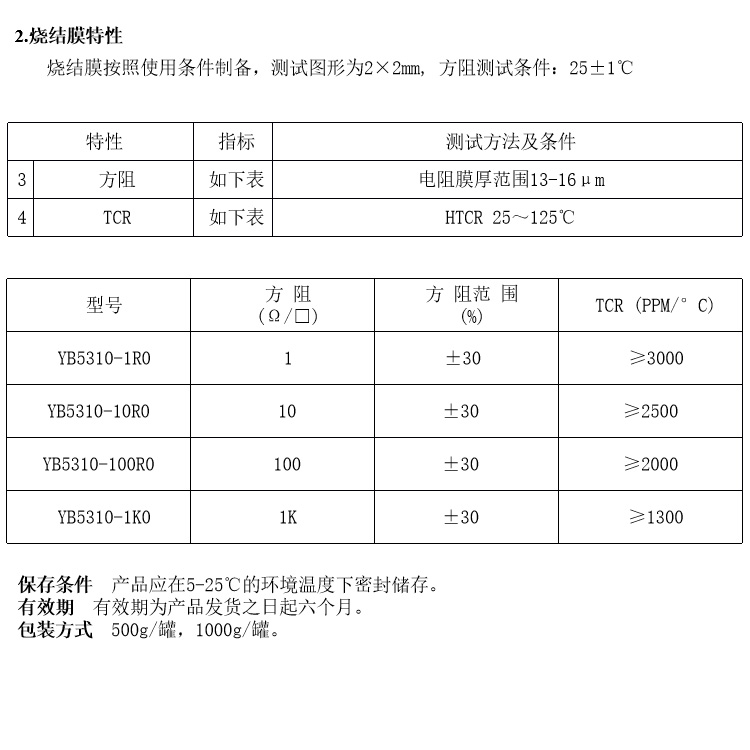

Sintering: Sintering the slurry at high temperature to form a strong bond between the conductive phase and the substrate, and adjust the resistance value.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2