Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

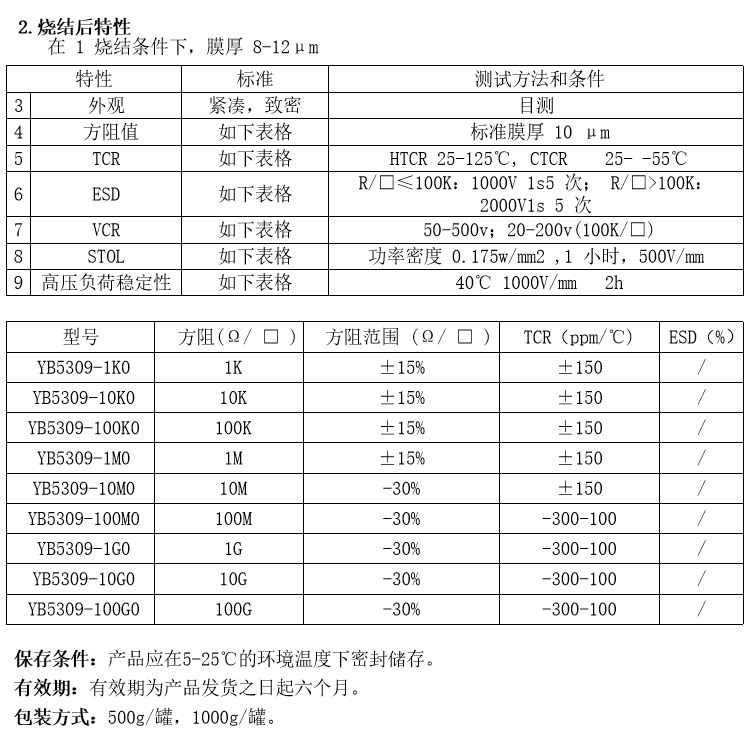

The resistor paste is designed specifically for high-voltage resistors, with strong high-voltage withstand capability and stable resistance value. The slurry is made of high-purity materials, and the resistance layer formed after sintering can withstand high voltage shocks without damage. Its excellent electrical and mechanical properties make high-voltage resistors widely used in fields such as power transmission and conversion.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

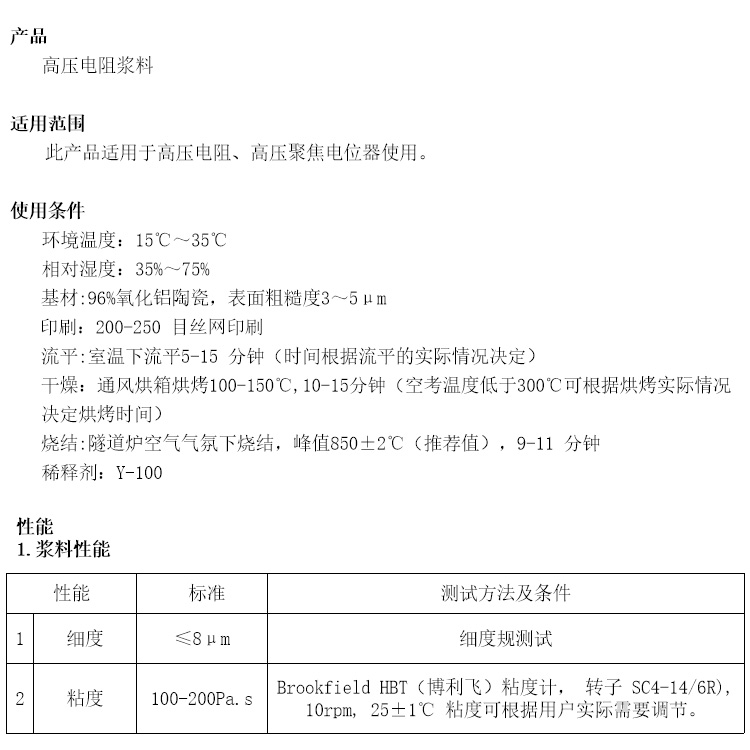

High voltage resistor paste is a paste made by mixing resistor material with conductive powder, adding appropriate binders and solvents as auxiliary materials, and undergoing special processing. This slurry can form a uniform and dense resistive film on the substrate, and after sintering and other processing techniques, form resistive elements with specific resistance values and high voltage resistance performance.

Product Features

High voltage endurance: High voltage resistor paste can withstand high voltages, ensuring the stability and safety of resistor components in high voltage environments.

Good electrical performance: with stable resistance value, low noise and inductance, suitable for the manufacturing of high-frequency circuits and precision electronic equipment.

Excellent thermal stability: able to maintain the stability of resistance values at different temperatures, avoiding resistance fluctuations caused by temperature changes.

Good mechanical performance: It has high hardness and wear resistance, and can maintain the integrity and stability of the resistance film in harsh environments.

Easy to process: Resistive films can be easily formed on substrates through processes such as screen printing, improving production efficiency and yield.

Production process

Material selection and proportioning: Based on the target resistance value and performance requirements, select suitable raw materials such as resistance materials, conductive powders, binders, and solvents, and carry out precise proportioning.

Mixing and Stirring: Fully mix and stir the well proportioned raw materials in the mixing equipment to ensure uniform dispersion of each component.

Printing and curing: The mixed slurry is printed on the substrate through screen printing and other processes to form a uniform resistive film layer. Then, after drying, sintering and other curing treatments, the resistance film layer is firmly attached to the substrate.

Performance testing and adjustment: Conduct performance testing on the cured resistor components, including testing of resistance values, voltage resistance, temperature coefficient, and other indicators. Adjust and optimize the preparation process based on the test results.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2