Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

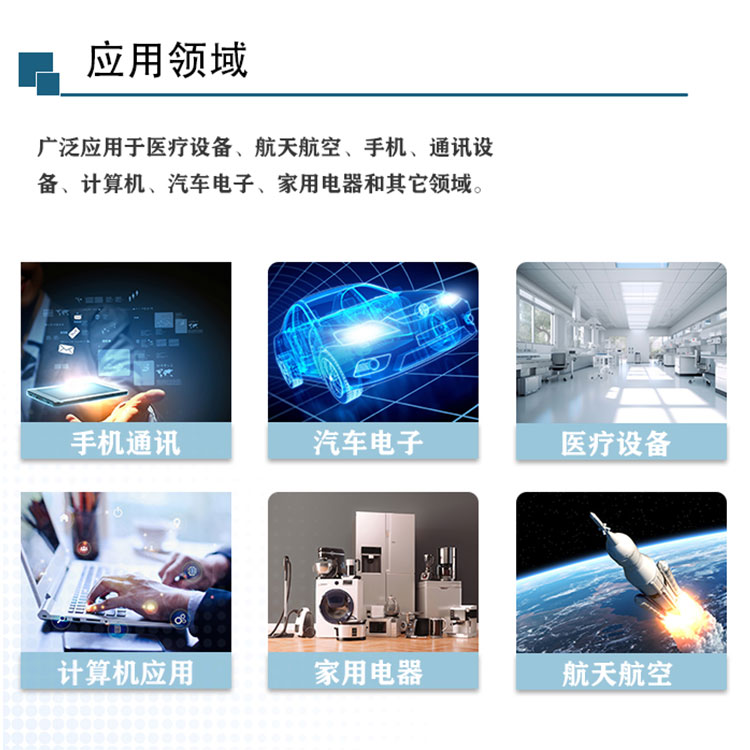

Environmentally friendly resistor paste is made from non-toxic and harmless raw materials, and complies with environmental standards such as RoHS and REACH. This slurry will not cause environmental pollution during manufacturing and use, and is a green and sustainable solution for resistor slurry. Its performance is stable and reliable, and it is widely used in the manufacturing of electronic products with high environmental requirements.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

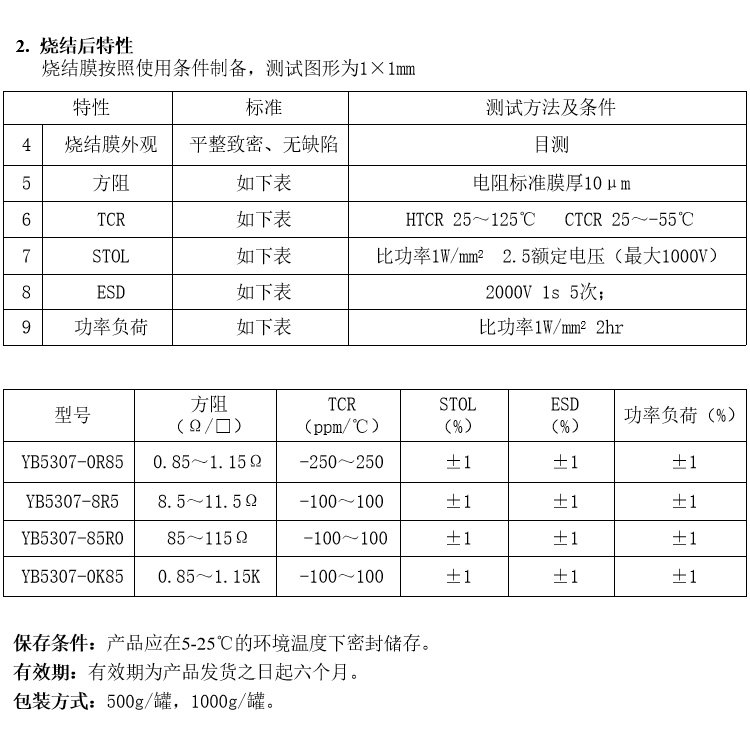

Environmentally friendly resistor paste is a material specifically designed for manufacturing resistors to reduce its impact on the environment. This type of slurry is mainly used in thick film technology, where the slurry is deposited on a ceramic substrate through screen printing or similar techniques, and then sintered to form resistive elements. The characteristics of environmentally friendly resistor paste lie in the selection of its components and preparation methods, aimed at avoiding the use of toxic or harmful substances while maintaining or improving the performance of the product.

Product Features

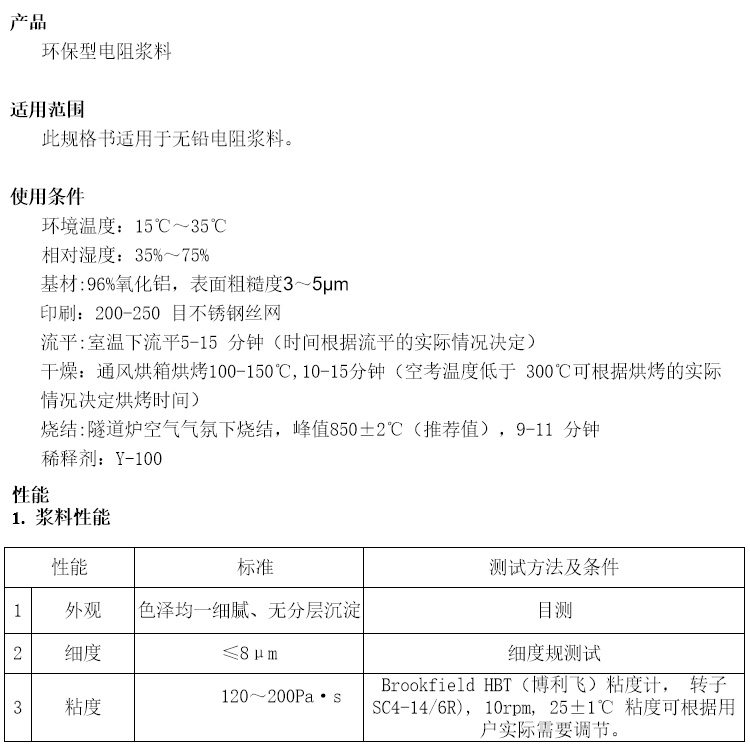

Lead free components: Traditional slurries may contain lead as part of the solder or glass phase, while environmentally friendly slurries use lead-free alloys or other harmless materials as substitutes.

Low toxicity: Avoid using heavy metals and other toxic substances such as cadmium and mercury to ensure minimal impact on the environment and human health during production, use, and disposal stages.

High compatibility: It has good adhesion and compatibility with various substrates (such as ceramics), ensuring the reliability and durability of resistors.

Excellent electrical performance: with stable resistance value, good temperature coefficient, high insulation strength and dielectric properties, ensuring the stable operation of electronic devices.

Production process

Raw material preparation: Select environmentally friendly materials such as metal oxides, conductive fillers, adhesives, etc., and finely grind and mix them.

Slurry preparation: Mix the ground raw materials in a certain proportion, add an appropriate amount of solvent and additives, and make a uniform resistance slurry through stirring and other processes.

Coating and drying: Apply the resistance paste onto the substrate to form a uniform resistance film. Then, the solvent and moisture are removed through a drying process to solidify the resistive film.

Sintering: For the resistor slurry that needs to be sintered, place the dried sample in a sintering furnace and perform sintering treatment at high temperature to form a dense structure of the resistor film.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2