Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The advanced technology oil level sensor resistor paste adopts a special formula, which has a low temperature coefficient of resistance and excellent printing characteristics. The resistance layer formed by sintering the slurry is uniform and stable, which can accurately reflect changes in oil level and provide reliable signal output for oil level sensors. It has excellent oil and corrosion resistance, and is suitable for oil level detection in various harsh environments.Come to our information center to learn moreTechnical data of resistance paste!

+86-13826586185

Oil level sensor resistor paste is a conductive material designed specifically for oil level sensors. It is widely used in fields such as automobiles, motorcycles, and industrial equipment to measure the liquid level height in oil tanks or storage tanks. The slurry is coated on the sensor substrate through a specific process to form a resistance layer. When the liquid level changes, the resistance value will correspondingly change, thereby achieving accurate measurement of the liquid level.

Product Features

Corrosion resistance: As the oil level sensor needs to work in corrosive fuels or liquids, the resistance paste must have good corrosion resistance and be able to resist the erosion of substances such as water, ethanol, organic acids, sulfides, etc. in the fuel.

Wear resistance: During long-term use, the resistance paste needs to withstand the sliding friction of the float or probe, so it must have good wear resistance to ensure the long-term stability and reliability of the sensor.

Conductivity: The conductivity of the resistor paste directly affects the measurement accuracy and sensitivity of the sensor, so it must have stable conductivity to ensure the accuracy of the measurement results.

Temperature stability: The oil level sensor may need to operate in different temperature environments, so the resistance paste needs to have good temperature stability to ensure consistency of measurement results at different temperatures.

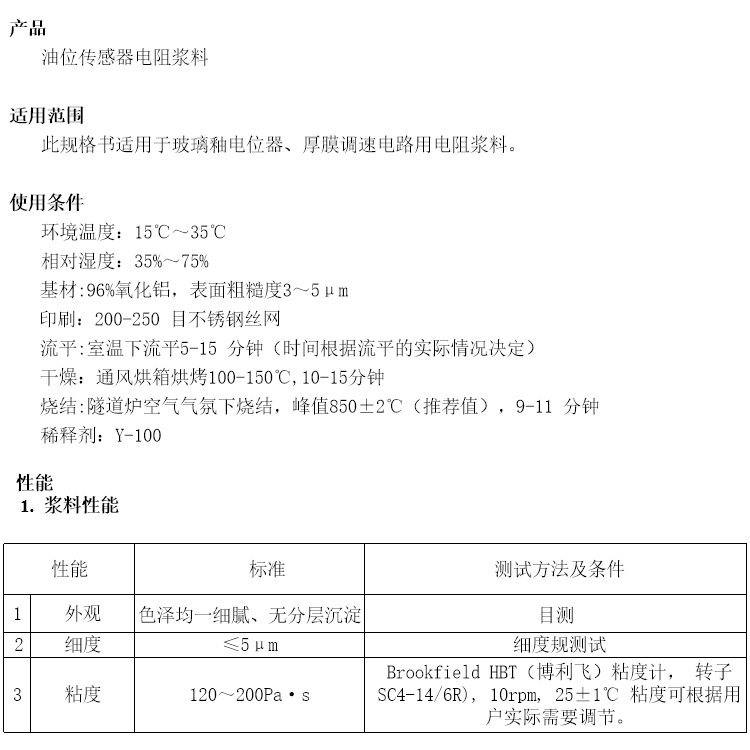

Production process

Formula design: Select appropriate conductive particles (such as carbon, metal powder), binders (organic or inorganic), and other additives based on performance indicators such as required resistance value and temperature coefficient.

Mixed preparation: Mix selected conductive particles, adhesives, and solvents in specific proportions to create a uniform slurry.

Coating: Using screen printing or other coating techniques to evenly apply the slurry onto a substrate (such as ceramic or plastic substrate).

Curing/Sintering: Heating causes the solvent to evaporate and the adhesive to solidify or sinter, forming a resistance layer with certain resistance characteristics.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2