Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

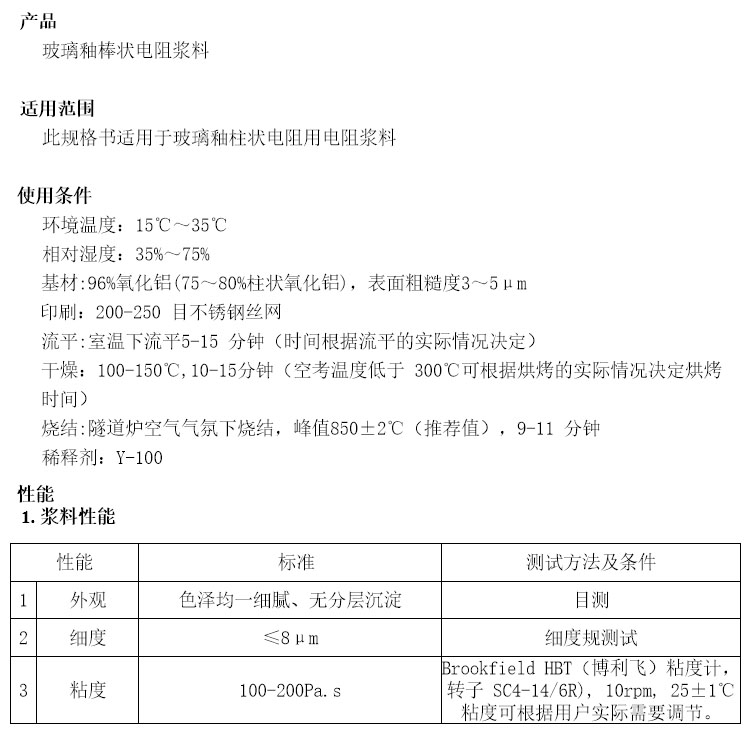

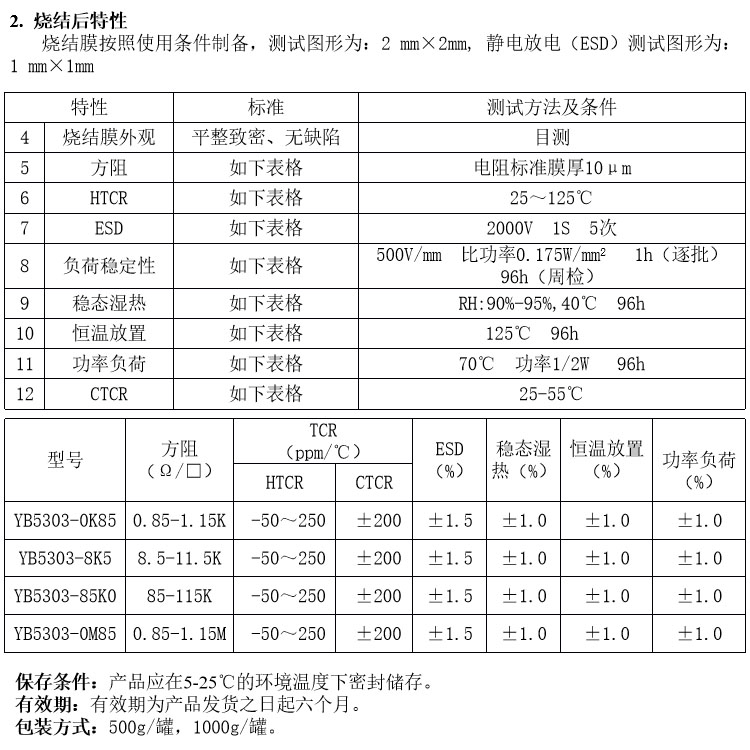

The glass glaze rod-shaped resistor paste is made by mixing precious metal oxides with glass glaze adhesive, and has excellent moisture and temperature resistance properties. It has a wide range of resistance values and good stability, making it an ideal choice for manufacturing high-precision and high reliability rod-shaped resistors. The resistance layer formed by sintering the slurry is dense and uniform, capable of withstanding large current shocks, and widely used in industrial automation, medical equipment, and other fields.Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Glass glaze rod-shaped resistor paste is a paste made by mixing metal oxides (such as palladium oxide, ruthenium oxide, etc.) of precious metals (such as silver, palladium, ruthenium, rhodium, etc.) with glass glaze adhesive. This slurry is processed through specific techniques and coated onto an insulating skeleton (which may be a rod-shaped structure made of ceramic or other insulating materials), and then sintered at high temperatures to form resistors with stable resistance values.

Product Features

Wide resistance range: Glass glaze resistors typically have a wide resistance range, ranging from 5.1 ohms to 200 megaohms (Ω), to meet the needs of different circuits.

Small temperature coefficient: The temperature coefficient of this resistor is small, which means that its resistance value does not change significantly with temperature and can maintain a stable resistance value over a wide temperature range.

Good moisture resistance: Glass glaze resistors have good moisture resistance and can maintain stable performance in humid environments.

Good high-frequency characteristics: suitable for high-frequency circuits, with low noise and good high-frequency response characteristics.

Small size and light weight: The rod-shaped design allows resistors to maintain high performance while having a smaller volume and weight, making them easy to integrate into electronic devices.

Production process

Raw material preparation: Select suitable precious metal oxides, glass glaze adhesives, and other auxiliary materials.

Mixing and stirring: Mix the raw materials in a certain proportion, and add an appropriate amount of solvent and additives for stirring to form a uniform slurry.

Coating: Apply the slurry onto the insulation skeleton to form a certain thickness of resistance layer.

Sintering: The coated insulation skeleton is sintered at high temperature to solidify the slurry into a stable resistance layer.

Testing and Inspection: Test and inspect the sintered resistors to ensure that their resistance values, temperature coefficients, and other performance indicators meet the requirements.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2