Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

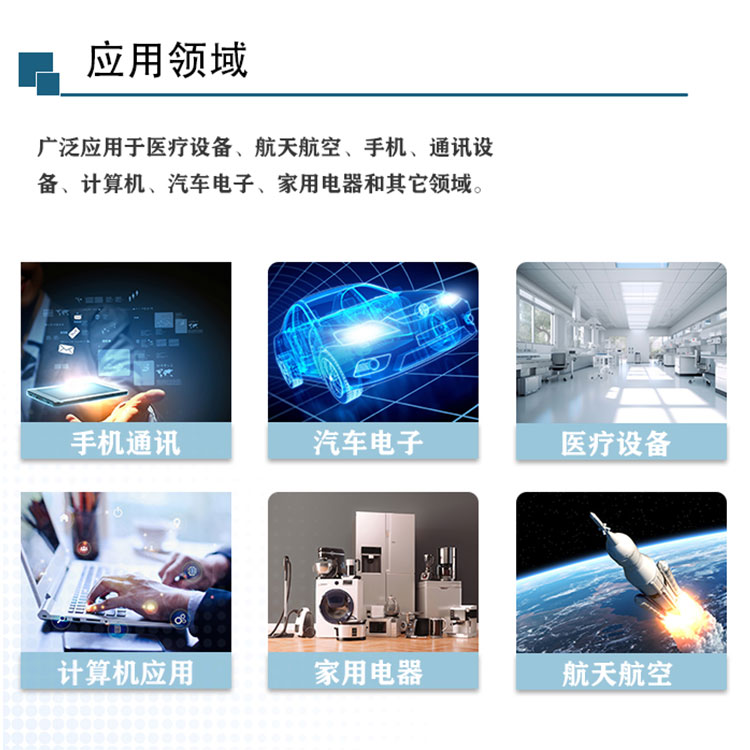

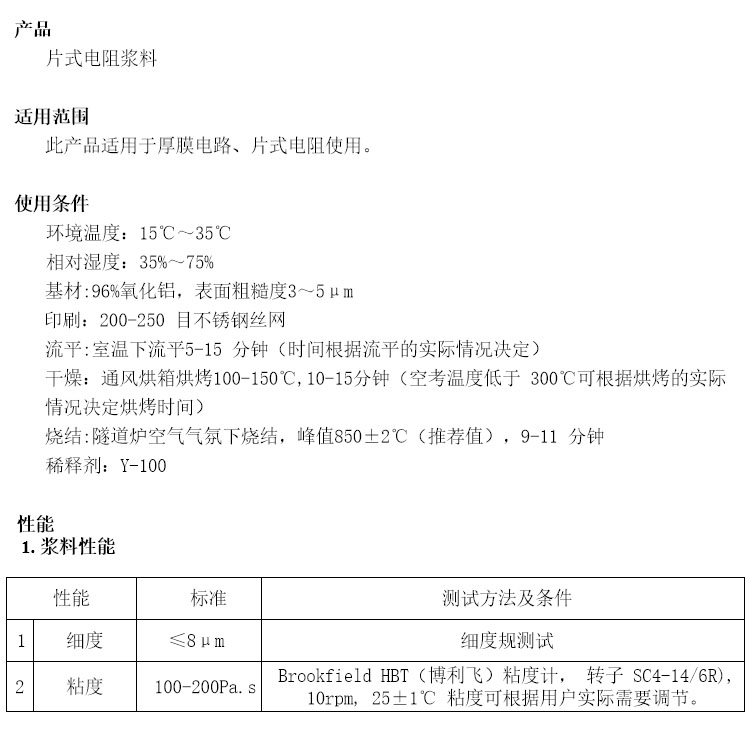

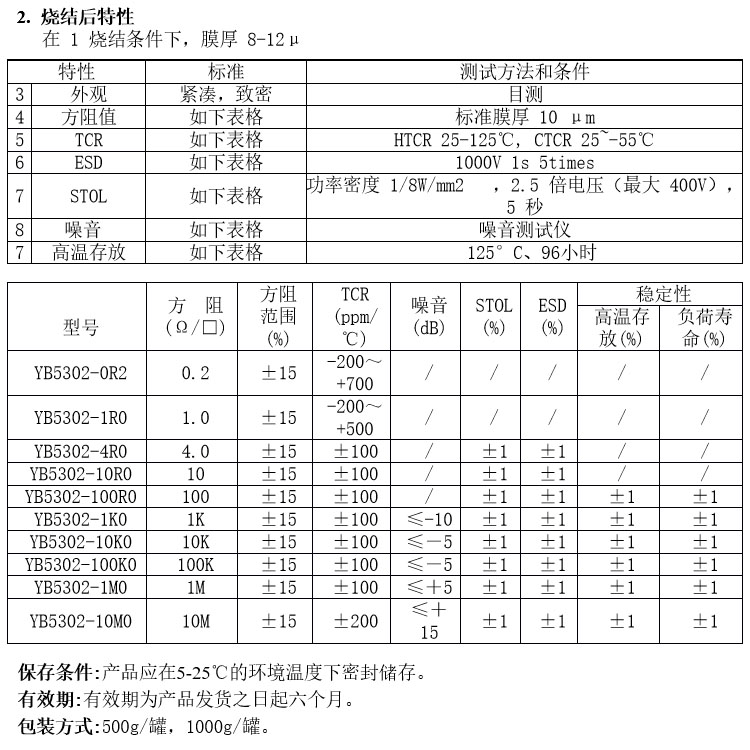

Chip resistor paste is specially developed for the manufacturing of chip resistors, with the characteristics of green environmental protection and high cost-effectiveness. The slurry formula is optimized, with a large coverage area, stable resistance value after sintering, and a small temperature coefficient. Its excellent printing characteristics and sintering performance make the production of chip resistors more efficient and the quality more reliable. Suitable for the manufacturing of chip resistors in fields such as consumer electronics, computers, and communication equipment. Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Chip resistor paste is mainly composed of various components such as conductive phase, glass phase, additives, and organic carriers, and is made through specific formulas and processes. It has good conductivity, high temperature resistance, electrical insulation, and corrosion resistance, which can ensure the stability and reliability of chip resistors in various working environments.

Product Features:

High temperature resistance: The chip resistor paste can withstand working in high temperature environments, ensuring the stability and reliability of the resistor under high temperature conditions.

Electrical insulation: The slurry has good electrical insulation to prevent current interference between resistors and other circuit components.

Corrosion resistance: able to resist corrosion from external environments such as chemicals and humidity, ensuring the long-term stability of resistors.

Adhesion: It can adhere well to the resistor substrate during the manufacturing process, ensuring a firm connection between the encapsulation layer and the resistor.

Adjustable: By adjusting the formula and process parameters of the slurry, resistors with different resistance values can be prepared to meet different circuit requirements.

Production process:

Raw material preparation: Prepare the required raw materials according to the production requirements, including conductive powder, polymer materials, solvents, etc.

Mixing: Mix conductive powder and polymer material in a certain proportion to form a slurry.

Coating: Apply the slurry evenly onto the resistor substrate to ensure uniform adhesion between the slurry and the substrate.

Curing: Place the resistor substrate coated with slurry into a curing device for curing treatment, so that the slurry forms a strong encapsulation layer.

Cutting and testing: Cut the cured resistor substrate into the required size and conduct resistance testing to ensure that the resistance value of the resistor meets the requirements.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2