Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Gold conductor paste, a model of excellent conductivity, designed specifically for high-precision microelectronic applications. The combination of high-purity gold powder and precision formula ensures low resistance and high stability. Widely used in integrated circuits and multi-layer wiring to enhance the performance and reliability of electronic devices. Excellent quality, leading the trend of microelectronics technology development.

+86-13826586185

Gold conductor paste is one of the honored products of Advanced Institute Company. It is composed of high-purity ultrafine gold powder, inorganic binder, and carrier. Gold conductor paste is a necessary material for thick film multilayer systems sintered in the atmosphere. By screen printing on the top, bottom, or middle layers, sintering is used to form thin, dense, and highly conductive conductors between multiple layers of wiring. It can also be used for drawing lines on sensor element electrodes and welding electrode leads. YB8113 gold conductor paste not only has excellent printing performance, but also has excellent hot pressing welding and corrosion resistance.

Main advantages

-Good conductivity

-High resolution of fine lines

-The effective coverage area of the slurry is high

1、 Typical applications: Used for hybrid integrated circuits, gas sensors, riot control devices, etc.

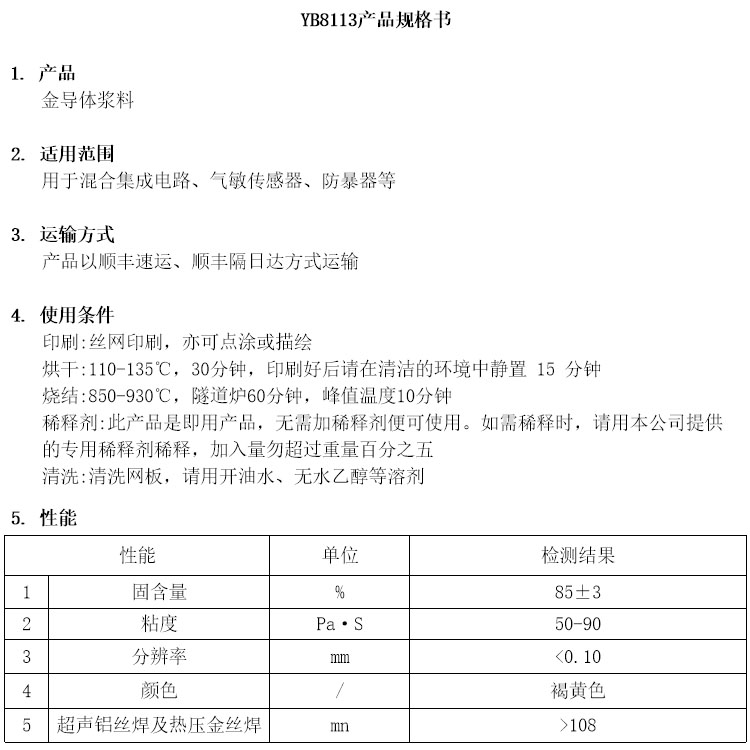

2、 Performance:

1. Conductive material: Gold

2. Solid content (in original tank): 85 ± 3%

3. Resolution:<0.10mm

4. Color: Brown Yellow

5. Viscosity: 50-90Pa. s

6. Ultrasonic aluminum wire welding and hot pressed gold wire welding: > 108mn

7. Storage period: Six months in original sealed packaging

3、 Burning performance:

1. Coverage: 73cm2/g/9 μ m

2. Electrical resistivity:<5m Ω□ (film thickness 8-12 μ m)

4、 Usage:

This product is used for screen printing and can also be dot coated or painted.

1. Mixing and application: Gently stir before use, not too fast, to prevent air from entering and generating bubbles.

2. Curing process (recommended):

a. Drying conditions: 110-135 ℃, 30 minutes. After printing, please let it stand in a clean environment for 15 minutes.

b. Sintering conditions: 850-930 ℃, tunnel furnace for 60 minutes, peak temperature for 10 minutes.

3. Dilution: This product is ready to use and can be used without the need for diluent. If dilution is required, please dilute with the specialized diluent provided by our company, and the amount added should not exceed 5% by weight.

4. Cleaning: To clean the mesh board, please use solvents such as oil-water and anhydrous ethanol.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2